[vc_row type=”vc_default” css=”.vc_custom_1474268037787{margin-bottom: -30px !important;padding-bottom: 30px !important;}”][vc_column offset=”vc_col-lg-12 vc_col-md-12 vc_col-xs-12″]

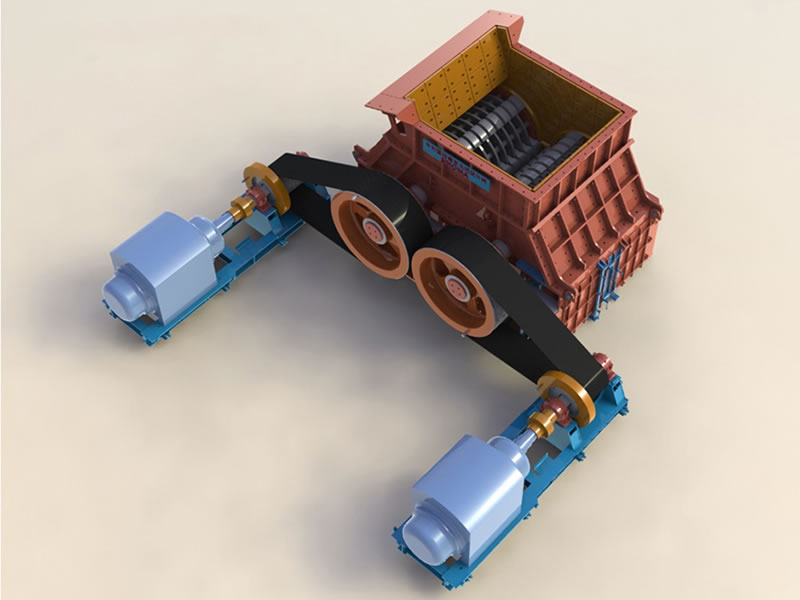

[ultimate_heading main_heading=”Hammer Crusher” alignment=”left” spacer=”line_only” spacer_position=”bottom” line_height=”4″ line_color=”” main_heading_font_size=”desktop:26px;” main_heading_line_height=”desktop:36px;” line_width=”50″ spacer_margin=”margin-top:15px;margin-bottom:30px;” el_class=”accent-border-color” main_heading_style=”font-weight:bold;”][/ultimate_heading][vc_column_text css=”.vc_custom_1610465865635{padding-bottom: 60px !important;}”]Hammer crushers are primarily used for breaking materials with a compression strength that is less than 200MPa, such as limestone, gypsum, coal, marlstone, and sandy shale in cement industries. The hammer crusher can crush the raw ore into small particles of 25mm in a single process, simplifying the process compared to traditional multi-stage crushing, thus saving customer investment costs. The hammer crushing equipment can also be added to a complete production line.[/vc_column_text][vc_text_separator title=”Components and spare parts” border_width=”3″ css=”.vc_custom_1610507302790{padding-top: 20px !important;padding-bottom: 20px !important;}”][/vc_column][vc_column width=”1/2″][/vc_column][vc_column width=”1/2″][/vc_column][vc_column][vc_column_text]Rotor

The rotor is the key part of the hammer crusher and comprises the rotor disc, end disc, hammer, hammer shaft, main shaft, belt pulley, bearing, and bearing seat.[/vc_column_text][vc_separator style=”dashed” border_width=”2″ el_width=”90″ css=”.vc_custom_1610470004936{padding-top: 20px !important;padding-bottom: 20px !important;}”][/vc_column][/vc_row][vc_row css=”.vc_custom_1610441144782{padding-bottom: 60px !important;}”][vc_column width=”1/3″]

[/vc_column][vc_column width=”1/3″][/vc_column][vc_column width=”1/3″][/vc_column][vc_column][vc_column_text]Hammer and rotor disc

The hammer and the rotor disc are made of ultra-high manganese steel. By casting with abrasion-resistant alloy rods, the service life is over 1.5 times that of common alloys.[/vc_column_text][vc_separator style=”dashed” border_width=”2″ el_width=”90″ css=”.vc_custom_1610470004936{padding-top: 20px !important;padding-bottom: 20px !important;}”][/vc_column][/vc_row][vc_row][vc_column width=”1/2″]

[/vc_column][vc_column width=”1/2″][/vc_column][vc_column][vc_column_text]Housing Casing

All the inner surfaces of the housing that come into contact with the mineral materials are protected by liner plates in order to prevent wear.[/vc_column_text][vc_separator style=”dashed” border_width=”2″ el_width=”90″ css=”.vc_custom_1610470004936{padding-top: 20px !important;padding-bottom: 20px !important;}”][/vc_column][/vc_row][vc_row][vc_column width=”1/2″]

[/vc_column][vc_column width=”1/2″][/vc_column][vc_column][vc_column_text]Crushing plate

The crushing plate is placed directly in front of the rotor, and the material size to be delivered is determined by the gap between the crushing plate and the rotating motor circle. It is made of high manganese steel through a casting process, with the maximum clearance designed to be the same as the maximum size of the discharged materials.[/vc_column_text][vc_separator style=”dashed” border_width=”2″ el_width=”90″ css=”.vc_custom_1610470004936{padding-top: 20px !important;padding-bottom: 20px !important;}”][/vc_column][/vc_row][vc_row][vc_column width=”1/4″]

[/vc_column][vc_column width=”1/4″][/vc_column][vc_column width=”1/4″][/vc_column][vc_column width=”1/4″][/vc_column][vc_column][vc_column_text]Grate

The grate is composed of cast high manganese steel grate bars. These grate bars are mounted at bottom of the rotor, covering almost all working surfaces with laying in a circumferential direction, thus wet materials can be easily removed.[/vc_column_text][vc_separator style=”dashed” border_width=”2″ el_width=”90″ css=”.vc_custom_1610470004936{padding-top: 20px !important;padding-bottom: 20px !important;}”][/vc_column][/vc_row][vc_row][vc_column width=”1/2″]

[/vc_column][vc_column width=”1/2″][/vc_column][vc_column][vc_column_text]Security door

By outfitting this equipment with a security door, foreign materials will be immediately discharged using centrifugal force, with the door automatically closing to prevent unprocessed materials from accidentally being removed. The security door can usually be left open when the required discharge size is large.[/vc_column_text][/vc_column][/vc_row][vc_row css=”.vc_custom_1610441187054{padding-bottom: 60px !important;}”][vc_column][vc_text_separator title=”Characteristics” border_width=”3″ css=”.vc_custom_1610470279950{padding-top: 20px !important;padding-bottom: 20px !important;}”][vc_column_text]

- If there are large-sized materials that cannot be crushed by the hammer in the first round, the belt pulley mounted on the shaft end will return to the rotor disc in order to ensure a stable rotor operation.

- Due to its large feeding size design, a variety of minerals can be fed into the crusher body.

- The materials can be crushed once by a hammer crusher, and then transferred to the grinding process.

- The hammer is designed with an entire rotation function, so the material impact on the rotor is significantly decreased.

- The crushing chamber is adjustable, thus reducing abrasion on wearing components.

- The rotor of this hammer crusher features great inertia and high rotating speed, and the linear velocity of the hammer reaches 30~35m/s.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_text_separator title=”Parameters” border_width=”3″ css=”.vc_custom_1610471604243{padding-top: 20px !important;padding-bottom: 20px !important;}”][vc_column_text]

| Model | Maximum feed size(mm) | Discharge size(mm,sieve residue≤10%) | Productive capacity (t/h) | Motor power(kW) |

|---|---|---|---|---|

| PCF2012/11 | 500×500×600 | ≤25 | 50-70 | 110 |

| PCF1609 | 600×600×600 | ≤25 | 50-70 | 90-110 |

| PCF1412 | 600×600×600 | ≤25 | 80-120 | 130-190 |

| PCF1616 | 800×800×800 | ≤25 | 150-240 | 250-350 |

| PCF1618 | 800×800×800 | ≤25 | 240-280 | 355-400 |

| PCF1818 | 800×800×1000 | ≤25 | 320-350 | 560-630 |

| PCF2018 | 1000×1000×1000 | ≤25 | 350-450 | 630-710 |

| NPC2025 | 1000×1000×1500 | ≤75 | 900-1000 | 900-1000 |

| 2NPC1818 | 1000×1000×1500 | ≤75 | 1000-1200 | 2×(560-630) |

| 2NPC1820 | 1000×1000×1500 | ≤75 | 1200-1300 | 2×(630-710) |