[vc_row type=”vc_default” css=”.vc_custom_1474268037787{margin-bottom: -30px !important;padding-bottom: 30px !important;}”][vc_column offset=”vc_col-lg-12 vc_col-md-12 vc_col-xs-12″]

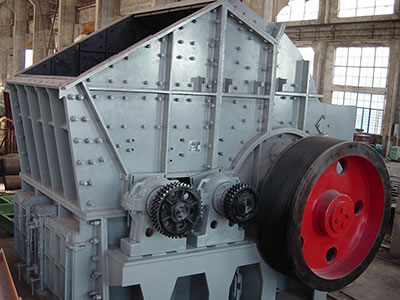

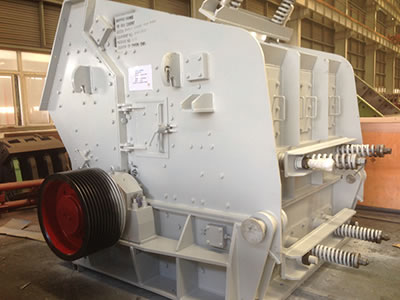

[ultimate_heading main_heading=”Lime Production Line” alignment=”left” spacer=”line_only” spacer_position=”bottom” line_height=”4″ line_color=”” main_heading_font_size=”desktop:26px;” main_heading_line_height=”desktop:36px;” line_width=”50″ spacer_margin=”margin-top:15px;margin-bottom:30px;” el_class=”accent-border-color” main_heading_style=”font-weight:bold;” margin_design_tab_text=””][/ultimate_heading][vc_column_text css=”.vc_custom_1610708933866{padding-bottom: 60px !important;}”]The lime production line comprises the vibrating feeder, jaw crusher, hammer crusher, impact crusher, circular vibrating screen, and belt conveyor. Depending on material properties and production requirements, we offer different production line configurations.Large limestone is transported uniformly from the raw material warehouse into the jaw crusher using a vibrating feeder, allowing coarse crushing to be efficiently carried out by the jaw crusher. The coarse crushed stone is then moved to the impact crusher for fine crushing. Finely crushed limestone is then transported to the vibrating screen to obtain different stone sizes. All stones that meet granularity requirements are transported to the stockpile using the belt conveyor.[/vc_column_text][vc_text_separator title=”Advantages” border_width=”3″ css=”.vc_custom_1610709097094{padding-top: 30px !important;padding-bottom: 30px !important;}”][vc_column_text]

- Advanced technology

Two-stage production process: A large jaw crusher is used in the first stage. The feed end is equipped with a vibrating screen feeder to ensure limestone cleanliness. A single stone crusher and two circular vibrating screens are used in the second stage. - High level of automation and easy to operate

Equipped with an advanced electronic control operating system with a high level of automation: With a simple workflow, the whole production line is easy to operate. Besides, no human operators are needed to carry out anything but on/off and routine maintenance. - Uniform granularity and high quality of finished products

This equipment solves problems that lead to poor stone shapes resulting from traditional equipment production. With high quality, uniform granularity, excellent stone shape, and low stone powder output rate, the finished product fully conforms to China’s highway material requirements. - High economic returns

Overcoming the shortcomings of high production costs for traditional equipment and damages caused to materials during production, our equipment results in higher output and efficiency, lower operation costs, and a high economic return.

[/vc_column_text][vc_text_separator title=”Supporting equipment” border_width=”3″ css=”.vc_custom_1610709085743{padding-top: 30px !important;padding-bottom: 30px !important;}”][/vc_column][vc_column width=”1/4″]

[ultimate_heading main_heading=”Jaw Crusher” heading_tag=”h6″ margin_design_tab_text=””][/ultimate_heading][/vc_column][vc_column width=”1/4″][ultimate_heading main_heading=”Hammer Crusher” heading_tag=”h6″ margin_design_tab_text=””][/ultimate_heading][/vc_column][vc_column width=”1/4″][ultimate_heading main_heading=”Impact Crusher” heading_tag=”h6″ margin_design_tab_text=””][/ultimate_heading][/vc_column][vc_column width=”1/4″][ultimate_heading main_heading=”Feeding Machine” heading_tag=”h6″ margin_design_tab_text=””][/ultimate_heading][/vc_column][/vc_row]