[vc_row type=”vc_default” css=”.vc_custom_1474268037787{margin-bottom: -30px !important;padding-bottom: 30px !important;}”][vc_column offset=”vc_col-lg-12 vc_col-md-12 vc_col-xs-12″]

[ultimate_heading main_heading=”Slag Crushing and Grinding Plant” alignment=”left” spacer=”line_only” spacer_position=”bottom” line_height=”4″ line_color=”” main_heading_font_size=”desktop:26px;” main_heading_line_height=”desktop:36px;” line_width=”50″ spacer_margin=”margin-top:15px;margin-bottom:30px;” el_class=”accent-border-color” main_heading_style=”font-weight:bold;”][/ultimate_heading][vc_column_text css=”.vc_custom_1611734475780{padding-bottom: 60px !important;}”]Capacity: 300~1,000 thousand tons/yearFeed Material Size: 2 mm~10 mm

Feed Material: Powdered material like feldspar, calcite, steatite, barite, fluorite, tombarthite, marble, ceramics, bauxite, manganese ore, and phosphorus rock.

We specialize in offering slag powder production line design, including the design, production, and delivery of the vertical mill, installing equipment sets, and general contracting of the production line construction.

Process: Slag Drying Machine → Extrusion Press→ Agglomerator →Powder Separator (Fine Powder) →Superfine Grinding Mill → Finished Product[/vc_column_text][/vc_column][vc_column]

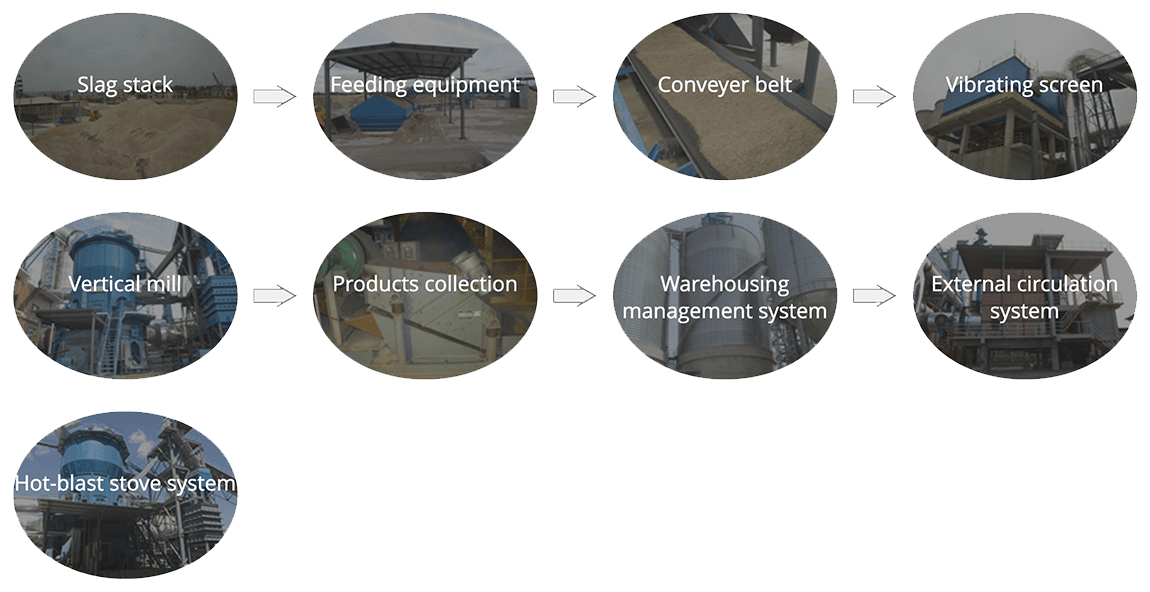

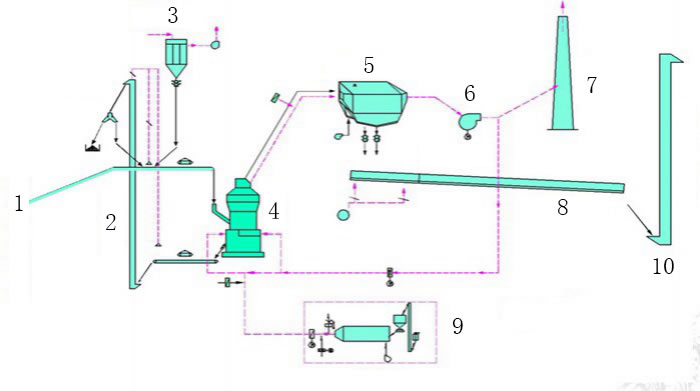

[/vc_column][/vc_row][vc_row css=”.vc_custom_1610441144782{padding-bottom: 60px !important;}”][vc_column][vc_text_separator title=”Fine powder production line with vertical mill operation process” border_width=”3″ css=”.vc_custom_1610689661948{padding-top: 20px !important;padding-bottom: 20px !important;}”][/vc_column][vc_column width=”1/2″][/vc_column][vc_column width=”1/2″][vc_column_text]- Slag feeding equipment

- Elevator

- Dust collector

- Vertical mill

- Powder collector

- Fan

- Funnel

- Conveyer belt

- Hot-blast stove

- Finished product storage

[/vc_column_text][/vc_column][vc_column][vc_column_text]

- The stacked slag is taken and fed by the forklift and conveyed using the belt conveyor.

- The slag is transported by the elevator into the vertical mill for grinding. The slag powder is then collected by the powder separator and dried using a hot blast stove.

- The dried slag powder is transported into the vertical mill for regrinding, after which the slag powder will be collected using a powder separator. The qualified powder is moved to the finished product warehouse.

[/vc_column_text][/vc_column][/vc_row]